TAEC

TAEC can be used for the market segments: polymer production, polymer crosslinking, thermoset composites and acrylics with their different applications/functions.

Categories:

Organic peroxide

|

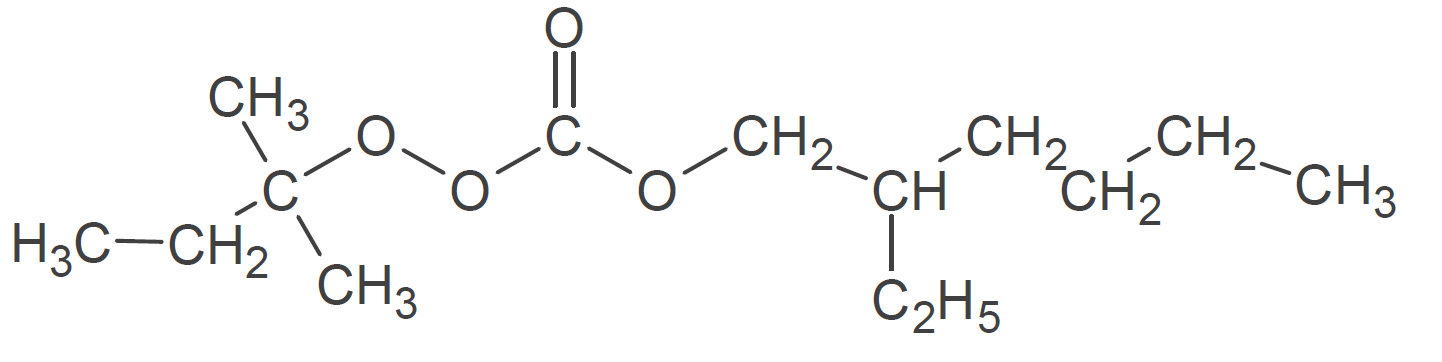

TAEC |

||

|

|

Molecular formula |

C14H2804 |

|

Molecular weight |

260.4 |

|

|

CAS NO. |

70833-40-8 |

|

|

UN NO. |

3105 |

|

|

CN NO. |

274-919-2 |

|

|

Chemical name |

tert-Amylperoxy 2-ethylhexyl carbonate |

|

Brief Introduction:

TAEC is an initiator for (co)polymerization of acrylates and methacrylates.

Theoretical Active OOxygen 6.14%

Half Life Data:

0.1hr,Half Life Temp..............134℃

1hr,Half Life Temp...................113℃

10hr,Half Life Temp.................95℃

Specification:

|

Appearance |

Clear liquid |

|

Assay |

≥98.5% |

|

Active oxygen |

5.77-6.14% |

|

Hydroperoxides as TAHP |

≤0.20% |

|

Inorganic +organic hydrolysable chloride |

≤100mg/kg |

|

Viscosity,20℃ |

6.5mPa.s |

Application:

TAEC can be used for the market segments: polymer production, polymer crosslinking, thermoset composites and acrylics with their different applications/functions.

Package and Storage:

The standard packaging is a 30-liter HDPE can for 25 kg peroxide content. Both packaging and transport meet the international regulations. For the availability of other packed quantities consult us.

Due to the relatively unstable nature of organic peroxides, a loss of quality can be detected over a period of time.

To minimize the loss of quality, we recommends a maximum storage temperature (Ts max.) for each organic peroxide product.

Ts Max.:30℃(86°℉)

Note

When stored according to these recommended storage conditions, TAEC will remain within the specifications for a period of at least 3 months after delivery.

Safety and handling

Keep containers tightly closed. Store and handle in a dry well-ventilated place away from sources of heat or ignition and direct sunlight. Never weigh out in the storage room. Avoid contact with reducing agents (e.g.amines), acids, alkalis and heavy metal compounds (e. g. accelerators, driers and metal soaps).Please refer to the

Safety Data Sheet (SDS) for further information on the safe storage, use and handling of TAEC. This information should be thoroughly reviewed prior to acceptance of this product.

Key words:

FAQ

What is organic peroxide?

What are organic peroxides used for?

What should be noted when storing organic peroxides?

Can you supply Custom synthesis service?

Get A Quote

Leave your contact information and get a free product quote

Application Areas

Products

Dicumyl peroxide is white crystalline.Melting point of 41-42℃. Relative density of 1.082.Decomposition temperature 120-125℃ room temperature stable. Gradually become yellowish under light. insoluble in water, soluble in ethanol, ether,acetic acid, benzene and petroleum ether.

BIPB is a white to yellowish powder or flake,Insoluble in water, partly dissolving in ethanol, ether, benzene, carbon tetrachloride and other organic solvents.

BPO 75% is a wet granular of diacyl peroxide, used as initiator of polymerization in expandable polystyrene(EPS),acrylic resins and curing agent for unsaturated polyester resin and elastomers.

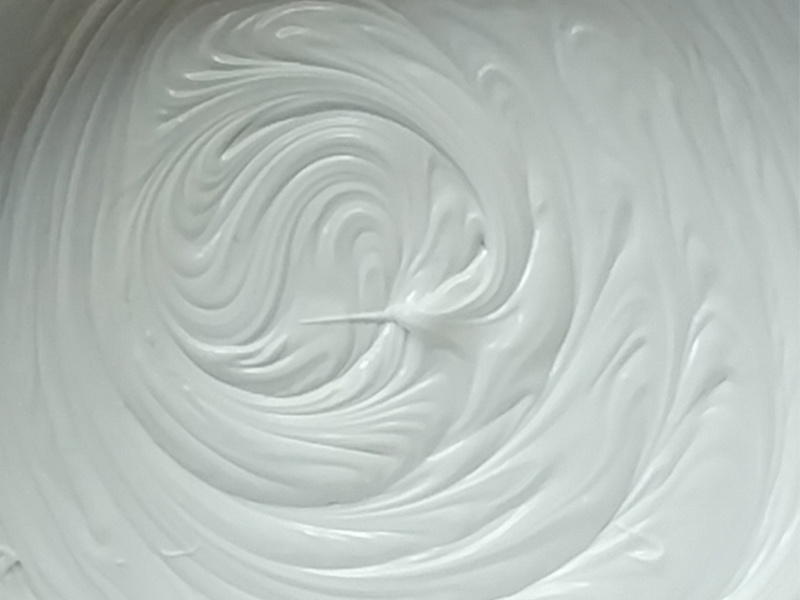

BPO 50% paste is a fine dispersion of dibenzoyl peroxide in a smooth,non-separating fire resistant creamy paste form,which can be easily dissolved in resins and monomers.This product is less hazardous and easier to use than technical or dry forms of dibenzoyl peroxide.Slightly soluble in alcohols,petroleum solvents,insoluble in chlorinated solvents.

Phone/WhatsApp:

Email:

About Us

Changzhou JOHO Chemical Co., Ltd., a subsidiary of Shanghai ICASON New Material Co., Ltd., represents the Group's strategic focus on polymer crosslinking, curing, and initiation technologies.

HUATAO GROUP

Products

Quick Access

Leave A Message

Leave your contact information and get a free product quote